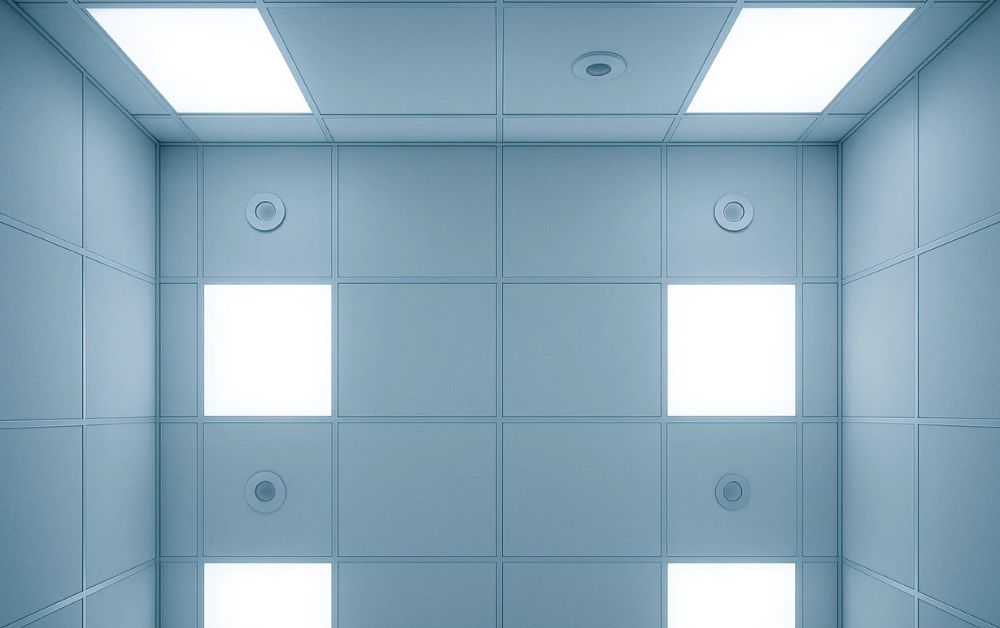

Cleanrooms are specialized environments designed to control contamination, regulate air quality, and ensure precise environmental conditions for sensitive operations. Industries such as pharmaceuticals, biotechnology, semiconductors, and healthcare heavily depend on these systems to protect products from impurities. However, it is not only about safeguarding products—clean room systems also play a vital role in ensuring worker safety and comfort.

In industries where employees spend long hours in controlled environments, worker well-being is directly linked to productivity and compliance. This blog explores how cleanroom systems are engineered to protect workers while maintaining comfort in highly controlled settings.

The Dual Purpose of Cleanroom Systems

Cleanroom systems serve two main purposes:

- Contamination Control – preventing harmful particles from affecting sensitive products or processes.

- Worker Protection and Comfort – ensuring employees are shielded from hazardous substances while working in a safe and ergonomic environment.

Balancing these two goals requires advanced technology, precise engineering, and continuous monitoring.

Air Filtration for Health Protection

One of the primary ways cleanrooms protect workers is through advanced air filtration. Cleanroom systems employ HEPA (High-Efficiency Particulate Air) & ULPA (Ultra-Low Penetration Air) filters to remove particles, microbes, and contaminants from the air.

- How it ensures safety: Workers are not exposed to harmful airborne particles, toxic fumes, or infectious microorganisms. This is especially critical in pharmaceutical and biomedical facilities.

- How it ensures comfort: Constant airflow ensures a steady supply of fresh, clean air, reducing the feeling of stuffiness or poor air circulation.

By maintaining high indoor air quality, these systems support both safety and long-term worker health.

Regulation of Temperature and Humidity

Working for extended periods in uncomfortable temperature or humidity can affect worker efficiency and health. Cleanroom systems are equipped with HVAC controls that regulate temperature and humidity precisely.

- Safety aspect: Stable humidity levels prevent electrostatic discharge, which can pose safety risks in electronics and semiconductor manufacturing.

- Comfort aspect: A controlled environment prevents extreme heat or cold, helping workers remain comfortable and focused during long shifts.

This balance ensures workers can perform demanding tasks with minimal discomfort.

Pressure Control to Prevent Contamination

Cleanrooms are designed with controlled air pressure—either positive pressure (to keep contaminants out) or negative pressure (to contain hazardous substances inside).

- For worker safety: In facilities dealing with harmful chemicals or infectious agents, negative pressure cleanrooms ensure that dangerous particles do not escape into surrounding areas, protecting staff and the broader workplace.

- For worker comfort: Maintaining stable air pressure eliminates drafts or uneven air circulation, creating a more comfortable environment for employees.

Ergonomic Design of Workspaces

Cleanroom systems are not only about air quality—they also encompass the layout, furniture, and movement flow within the workspace.

- Safety considerations: Equipment is arranged to minimize unnecessary movement and reduce exposure to sensitive processes. Materials are chosen to be smooth and easy to sanitize, preventing accidental contamination.

- Comfort considerations: Ergonomic workstations, adjustable seating, and carefully designed workflows help reduce physical strain on workers.

By integrating safety and comfort in workspace design, cleanrooms promote higher efficiency and reduced fatigue.

Protective Clothing Integration

Workers in cleanrooms wear specialized garments such as gowns, gloves, masks, and goggles to minimize contamination risks. Cleanroom systems are designed with air showers, gowning rooms, and pass-through chambers to support these protective measures.

- Safety: Prevents workers from carrying contaminants into the cleanroom or being exposed to hazardous particles inside.

- Comfort: Modern cleanroom garments are made with breathable and lightweight materials, reducing discomfort during long working hours.

The integration of clothing systems with cleanroom design ensures that workers can perform tasks safely without compromising on comfort.

Noise and Lighting Control

Worker comfort also depends on environmental factors such as noise and lighting.

- Noise control: Advanced cleanroom HVAC systems are engineered to operate quietly, reducing constant background noise that could cause stress or fatigue.

- Lighting control: Cleanroom lighting is designed to minimize glare, provide adequate brightness, and simulate natural light where possible, creating a more comfortable working atmosphere.

Both these factors significantly improve concentration and reduce strain on workers.

Monitoring and Safety Systems

Cleanroom systems include real-time monitoring for particle counts, temperature, humidity, and airflow. For workers, this provides:

- Immediate safety alerts: Systems detect and signal deviations, ensuring staff can take quick action if conditions become unsafe.

- Reassurance and comfort: Knowing that the environment is constantly monitored helps workers feel confident and focused on their tasks.

This constant vigilance is an unseen but vital layer of protection.

In Conclusion

Cleanroom systems are more than just technological solutions for contamination control; they are comprehensive environments designed to protect and support the workforce. From air quality management and temperature regulation to ergonomic workspace design and real-time monitoring, these systems ensure that workers remain safe, healthy, and comfortable while performing critical tasks.

For world-class, reliable, and industry-approved clean room systems, Prolux International LLC is a trusted partner offering tailored solutions to meet UAE’s stringent industrial and healthcare requirements.