When it comes to safety, gas detection is one area where there’s no room for shortcuts. Whether it’s a manufacturing plant, workshop, warehouse, or confined space, detecting gas leaks early can literally save lives — and prevent serious damage to property or operations.

But once you decide you need gas detection, the next question is: what kind?

The two most common options are portable & fixed gas detectors. They both do the same basic job — detecting dangerous gases — but they’re built for very different situations. Knowing the difference helps you choose what actually fits your work environment.

Why Gas Detection Matters

Every workplace that deals with gases — toxic, flammable, or oxygen-depleting — carries some level of risk. Even a small leak can create a hazardous situation in seconds.

Gas detection systems are designed to identify these problems before they get out of hand. They protect your team, keep your operations compliant with safety standards, and prevent costly downtime.

But how that protection works — whether through a portable device or a fixed system — depends on how & where you work.

Portable Detectors — Safety That Moves With You

A portable gas detector is exactly what it sounds like: a small, lightweight device that workers carry with them. It can be clipped to clothing or held in hand, & it continuously monitors the air around the person using it.

These detectors are ideal for jobs where workers move around frequently — like inspections, maintenance tasks, or entering confined spaces where gas levels might change unexpectedly.

Typical features include:

- Compact, wearable design

- Runs on battery power

- Alerts through sound, vibration, or flashing lights

- Some models can detect multiple gases at once

Why people like them:

- You can take them anywhere — perfect for changing job sites

- No installation needed — just switch it on and go

- Affordable and quick to deploy

- Gives each worker personal protection wherever they are

The downside: if someone forgets to wear it, or it’s not properly maintained, it can’t do its job. Regular calibration and training are key to keeping portable units reliable.

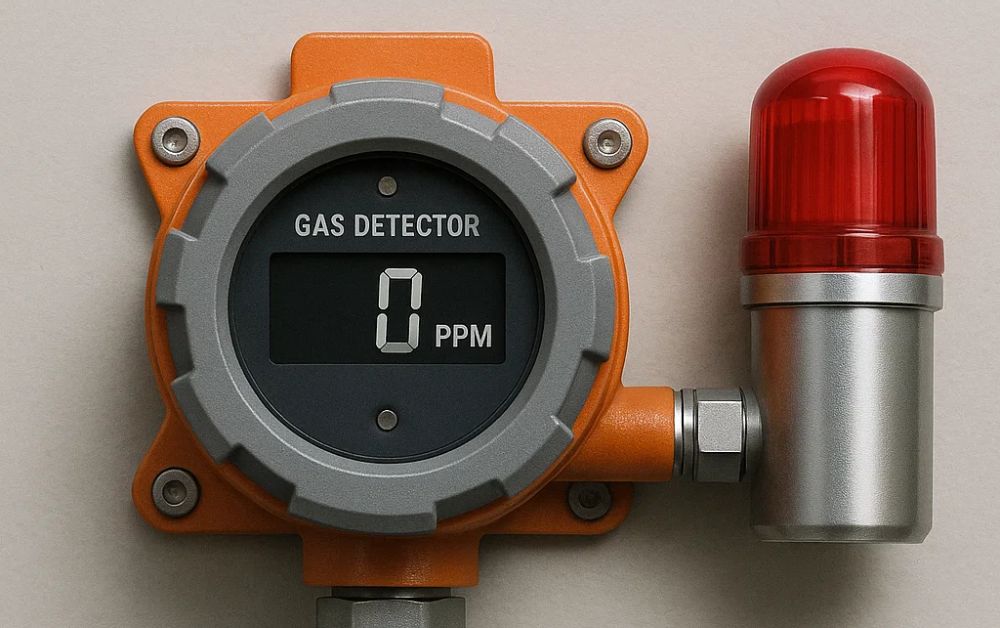

Fixed Detectors — Constant Protection in One Place

Fixed gas detection systems are the heavy-duty option. These are permanently installed devices that continuously monitor air quality in a specific area — like a factory floor, storage tank area, or plant room.

Once installed, they quietly monitor gas levels 24/7, triggering alarms or even shutting down equipment automatically if something goes wrong.

Typical features include:

- Mounted in areas where gas leaks are most likely

- Constant, real-time monitoring

- Integration with alarm systems, ventilation, or building management systems

- Centralized data collection for easier supervision

Their biggest advantages:

- Continuous protection — no human action needed

- Instant alerts across the facility

- Helps you stay compliant with industrial safety standards

- Can trigger automatic responses, like shutting off valves or starting ventilation

Of course, because these detectors are stationary, they only cover the area they’re installed in. For moving workers or changing conditions, portable units are still necessary.

Portable vs Fixed — The Main Differences

| Feature | Portable Detectors | Fixed Detectors |

| Mobility | Can move with workers anywhere | Installed permanently in one location |

| Monitoring | Personal, short-term monitoring | Continuous, area-based monitoring |

| Installation | None required | Requires professional setup |

| Power | Battery operated | Usually mains powered |

| Alerts | Alerts the user directly | Alerts the control room or entire facility |

| Best For | Confined spaces, inspections, mobile work | Industrial sites, plants, storage areas |

How to Choose the Right One

There’s no one-size-fits-all answer — it really depends on your operations.

You’ll probably need portable detectors if:

- Workers move between different job sites

- You do regular inspections or maintenance

- Gas hazards are temporary or unpredictable

You’ll want fixed systems if:

- The gas risk is constant or tied to one location

- You need continuous 24/7 monitoring

- You want the system linked to alarms or automatic shutoffs

In many cases, the safest and most practical solution is using both. Fixed systems provide broad area coverage, while portable units protect individuals working in or around those areas.

Making a Smart Safety Decision

Choosing a gas detection system isn’t just about ticking a compliance box — it’s about protecting people & keeping your operation running safely.

Start by assessing your risks:

- Where are the potential leak points?

- Are your workers stationary or mobile?

- Do you need monitoring 24/7 or only during certain tasks?

Once you have that picture, it is worth speaking to a professional who can design a system that fits your exact site conditions — rather than relying on guesswork or generic setups.

Final Thoughts

Both portable and fixed gas detectors are essential tools for maintaining safety — they just serve different purposes. Portable units protect individual workers, while fixed systems safeguard the entire facility.

The best approach is to combine the two for full coverage — keeping both your people and your property safe.

If you’re looking for guidance on the right setup or need reliable detection systems for your operation, Prolux International LLC offers expert advice and high-quality equipment designed for industrial & commercial environments across the UAE.