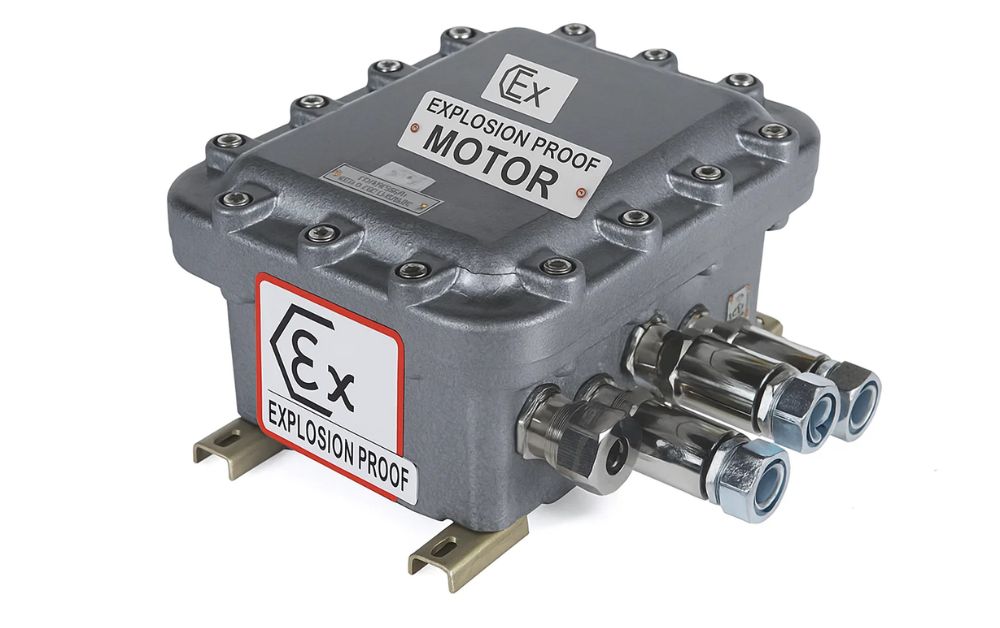

Explosion proof motors are essential in industries where there’s a high risk of fire or explosion from flammable gases, vapors, or dust. These motors are built to last and designed to keep workers safe, but like any machinery, they can run into problems if not properly maintained. Understanding the common causes of motor failure—and how to prevent them—can help keep your operations running smoothly and safely. Let’s take a closer look at the most common issues with explosion-proof motors and what you can do to avoid them.

Overheating Issues

Overheating is one of the most common problems affecting explosion-proof motors. Excessive heat can damage key components, such as insulation and bearings, which could eventually lead to motor failure. This often happens owing to factors such as overloading, poor ventilation, or blocked cooling channels.

How to Avoid It:

- Make sure the motor is sized correctly for its load and application.

- Regularly check and clean the ventilation paths, fans, or heat exchangers to keep air flowing freely.

- Use built-in sensors or external systems to monitor operating temperature and proactively address potential issues.

Properly managing heat not only ensures your motor runs efficiently but also decreases the risk of sparks or ignition in hazardous areas.

Bearing Failures

Bearings are must for the smooth operation of a motor, but they’re also vulnerable to wear and tear. If not correctly maintained, bearings can fail due to improper lubrication, misalignment, or contamination. When bearings fail, you’ll often hear strange noises or experience increased vibration, which could lead to a complete motor breakdown.

How to Avoid It:

- Stick to a regular lubrication schedule, using the right type and amount of lubricant.

- Make sure the motor and connected equipment are correctly aligned to avoid uneven stress.

- Consider using sealed bearings or protective covers to keep dust, moisture, or chemicals out.

Regular bearing maintenance will help you avoid downtime and extend the life of your motor.

Electrical Component Malfunctions

Electrical issues like insulation failure, short circuits, or winding damage are unfortunately common in explosion-proof motors, mainly in hazardous environments. These problems can occur owing to voltage spikes, moisture intrusion, or improper installation.

How to Avoid It:

- Always follow the manufacturer’s guidelines for electrical installation & grounding.

- Install surge protectors or voltage regulators to protect the motor from voltage fluctuations.

- Regularly test the insulation resistance to catch any potential issues early.

Maintaining the electrical integrity of your motor is crucial to ensuring it runs safely and efficiently without any risk of sparks or fire.

Contamination and Environmental Factors

Explosion-proof motors often operate in harsh environments where dust, chemicals, or moisture can cause contamination. This can affect key components such as insulation, bearings, & wiring. Even humidity and chemical corrosion can compromise the motor’s performance.

How to Avoid It:

- Use the appropriate enclosures and seals to prevent dust, moisture, or chemicals from entering the motor.

- Make it a habit to inspect and clean the motor, especially if it’s in a particularly dusty or corrosive environment.

- Apply corrosion-resistant coatings or use materials specifically designed for the environment in which your motor operates.

Proper protection against contaminants is essential for ensuring your motor stays reliable and compliant with safety standards.

Improper Maintenance Practices

The most common cause of motor failure is simply neglecting proper maintenance. Skipping inspections, failing to lubricate, or failing to replace worn-out parts can cause motors to fail prematurely. Regular maintenance is key to preventing breakdowns and avoiding costly repairs.

How to Avoid It:

- Develop a comprehensive maintenance schedule & stick to it.

- Train your staff to handle, inspect, and repair explosion-proof motors properly.

- Keep detailed maintenance logs to track performance & identify potential issues before they become significant problems.

Proactive maintenance aids catch minor issues before they escalate, reducing downtime and repair costs.

Mechanical Stress and Vibration

Vibration and mechanical stress can gradually wear down motor components, leading to misalignment, cracks, & even catastrophic failure. This is mainly true for motors handling heavy or fluctuating loads.

How to Avoid It:

- Perform regular vibration analysis to detect any early signs of imbalance or misalignment.

- Ensure the motor is properly mounted & aligned to reduce unnecessary mechanical strain.

- Use vibration-dampening pads or supports when appropriate to minimize stress.

Keeping vibration in check helps prevent structural damage & ensures the motor operates smoothly without unexpected breakdowns.

Misapplication of Motors

Using a motor for tasks it was not designed for can lead to severe damage. Whether it’s overloading, running at incorrect speeds, or using a motor in the wrong hazardous zone, misapplication is a serious risk.

How to Avoid It:

- Always pick a motor based on its load, speed, & the hazardous area classification it is meant to operate in.

- Double-check the manufacturer’s specifications and certifications to ensure the motor is suitable for your specific environment.

- Avoid modifying the motor in ways that could compromise its explosion-proof integrity or safety ratings.

Ensuring you use the correct motor for the right job is one of the simplest ways to avoid failures and keep things running safely.

In Conclusion

Explosion-proof motors are must for safe industrial operations, but they are susceptible to failures if not properly maintained, installed, or monitored. Overheating, bearing wear, electrical malfunctions, vibration, contamination, improper maintenance, & misapplication are common challenges that can be mitigated through careful design, preventive practices, and routine inspections.

By implementing these strategies, industries can maximize motor performance, extend operational life, & maintain a safe working environment. For high-quality, reliable, & compliant explosion-proof motors, Prolux International LLC provides advanced products & expert services tailored to meet stringent safety standards.