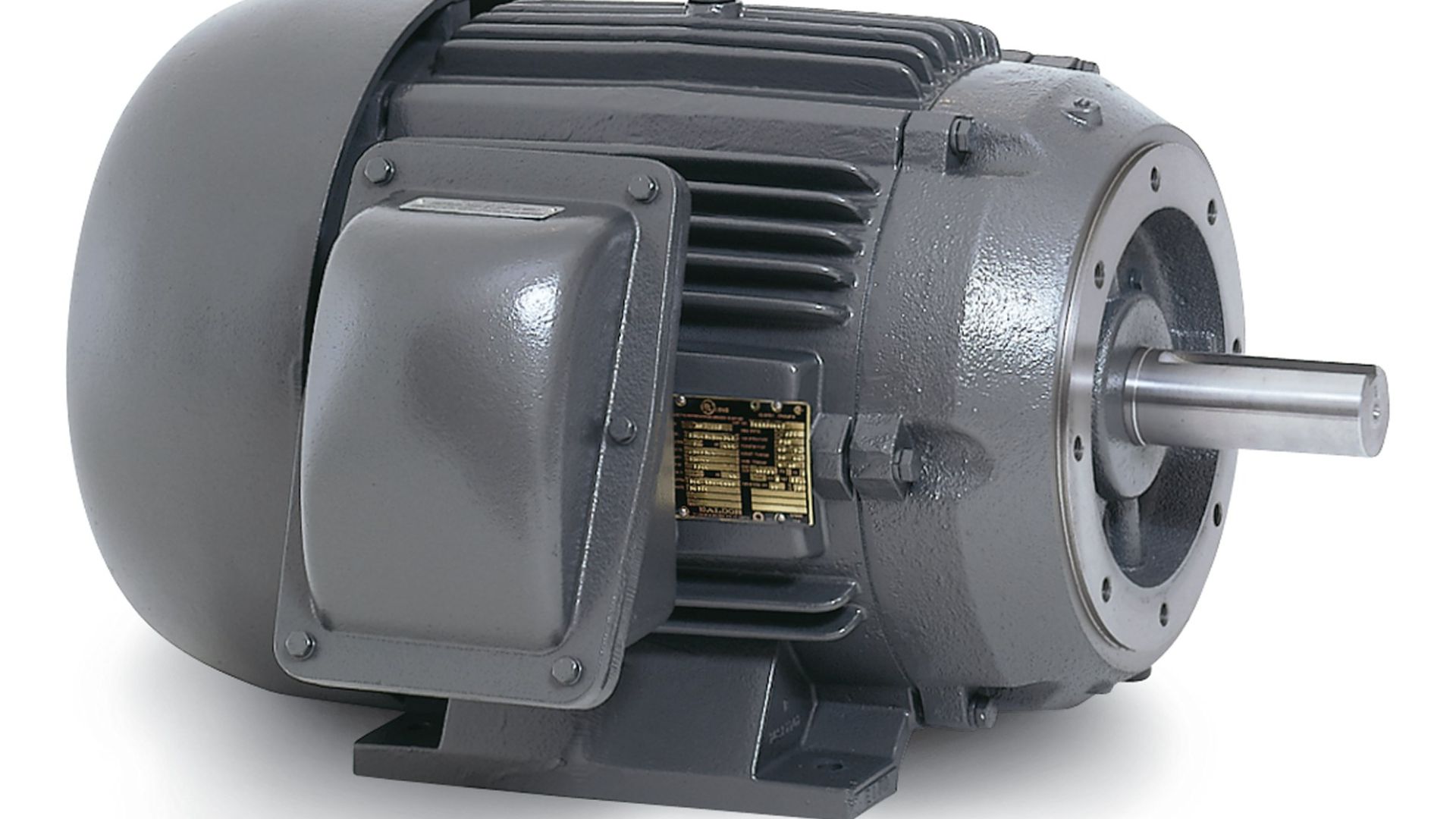

Explosion-proof motors and their associated services are essential in industries where there is a risk of potentially explosive atmospheres due to the presence of flammable gases, vapors, dust, or combustible materials. These motors are designed to operate safely in such hazardous environments, minimizing the risk of ignition and explosion. Explosion-proof motor services refer to the maintenance, repair, and support provided for these specialized motors to ensure their safe and reliable operation.

Industries that often require explosion-proof motors and related services include oil and gas, chemical processing, mining, food and beverage, pharmaceuticals, and manufacturing facilities where flammable substances are present. It’s crucial to engage with experienced and certified professionals to ensure the safe and compliant operation of these motors in hazardous environments.

What are the key aspects of the Explosion-proof motors supplier in UAE?

Following are some key aspects of explosion-proof motor services:

- Installation and Commissioning: Professionals experienced in hazardous area regulations must install explosion-proof motors to ensure they are properly integrated into the industrial process. This involves following specific guidelines and standards to prevent ignition sources.

- Maintenance: Regular maintenance is critical to ensure that explosion-proof motors remain in optimal working condition. Maintenance tasks may include cleaning, lubrication, inspection, and testing of electrical components to identify and rectify any issues.

- Repairs: When explosion-proof motors experience problems or damage, specialized repair services are required to address the issues without compromising safety. This often involves replacing damaged components or ensuring that seals and enclosures remain intact.

- Compliance and Certification: Explosion-proof motors must meet strict regulatory standards to be used in hazardous environments. Motor service providers help ensure that motors remain compliant with these standards and assist in obtaining the necessary certifications.

How Does Explosion-Proof Motors Enhance Safety in Hazardous Areas?

Explosion-proof motors enhance safety in hazardous areas by significantly reducing the risk of igniting flammable gases, vapors, dust, or combustible materials that may be present in these environments. Here are several ways in which explosion-proof motors contribute to safety:

- Enclosed Design: Explosion-proof motors are built with a robust, sealed enclosure that prevents any sparks, arcs, or excessive heat generated within the motor from escaping and igniting the surrounding atmosphere. The enclosure is typically designed to withstand pressure and prevent the passage of flammable materials.

- Explosion-Resistant Materials: These motors are constructed using materials that are highly resistant to explosion-related damage. The motor’s components, such as the housing and wiring, are made to withstand the force of an explosion without rupturing or causing further hazards.

- Effective Cooling: Explosion-proof motors incorporate efficient cooling systems to dissipate heat. This prevents overheating and minimizes the risk of ignition due to excessive temperatures.

- Sealed Terminal Boxes: Terminal boxes, where electrical connections are made, are sealed tightly to prevent the escape of sparks or arcs. This ensures that any electrical faults or hotspots are contained within the motor.

If you go through proper research surely you may come across varieties of services so in that case can get in touch with us at Prolux International