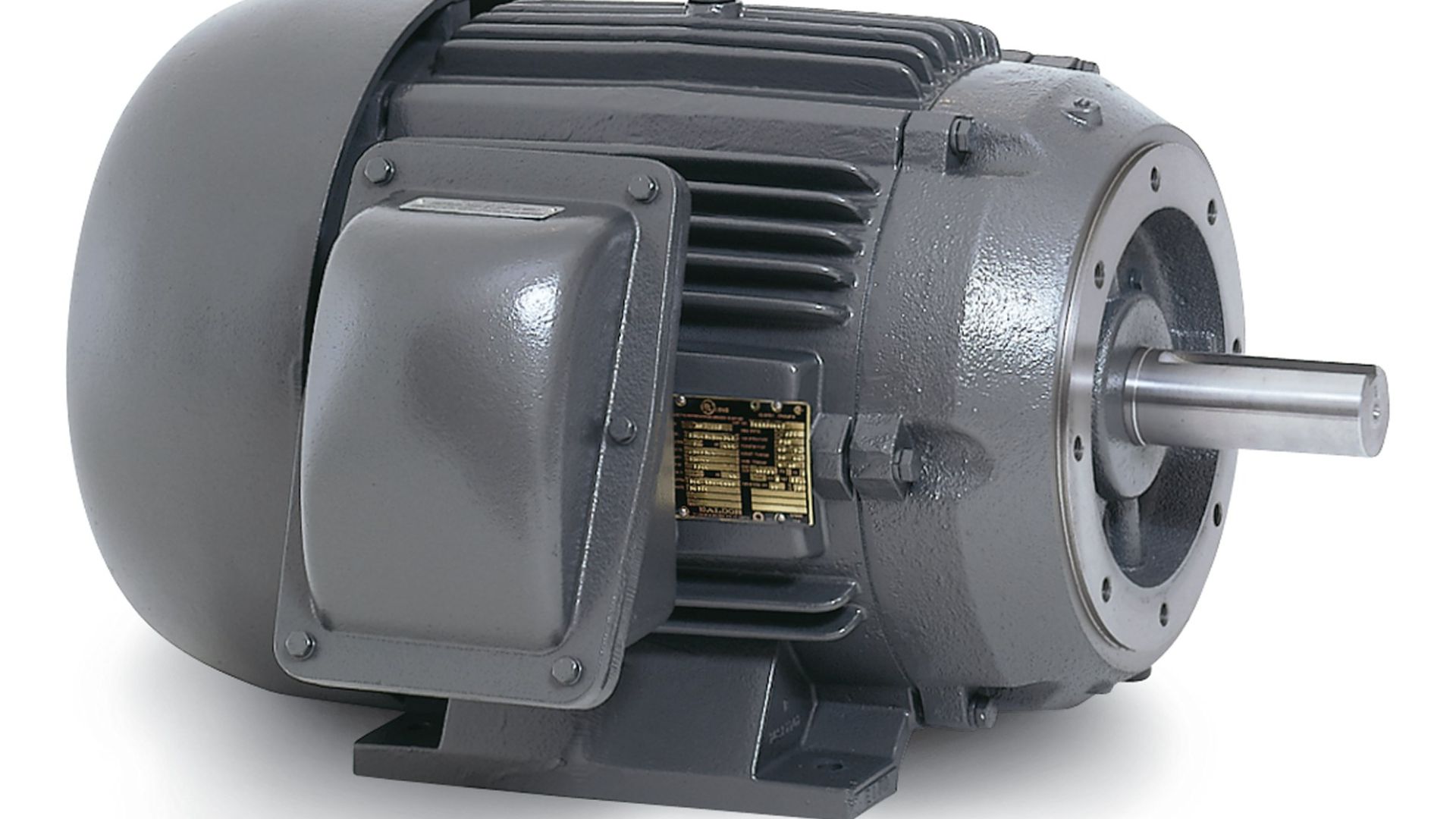

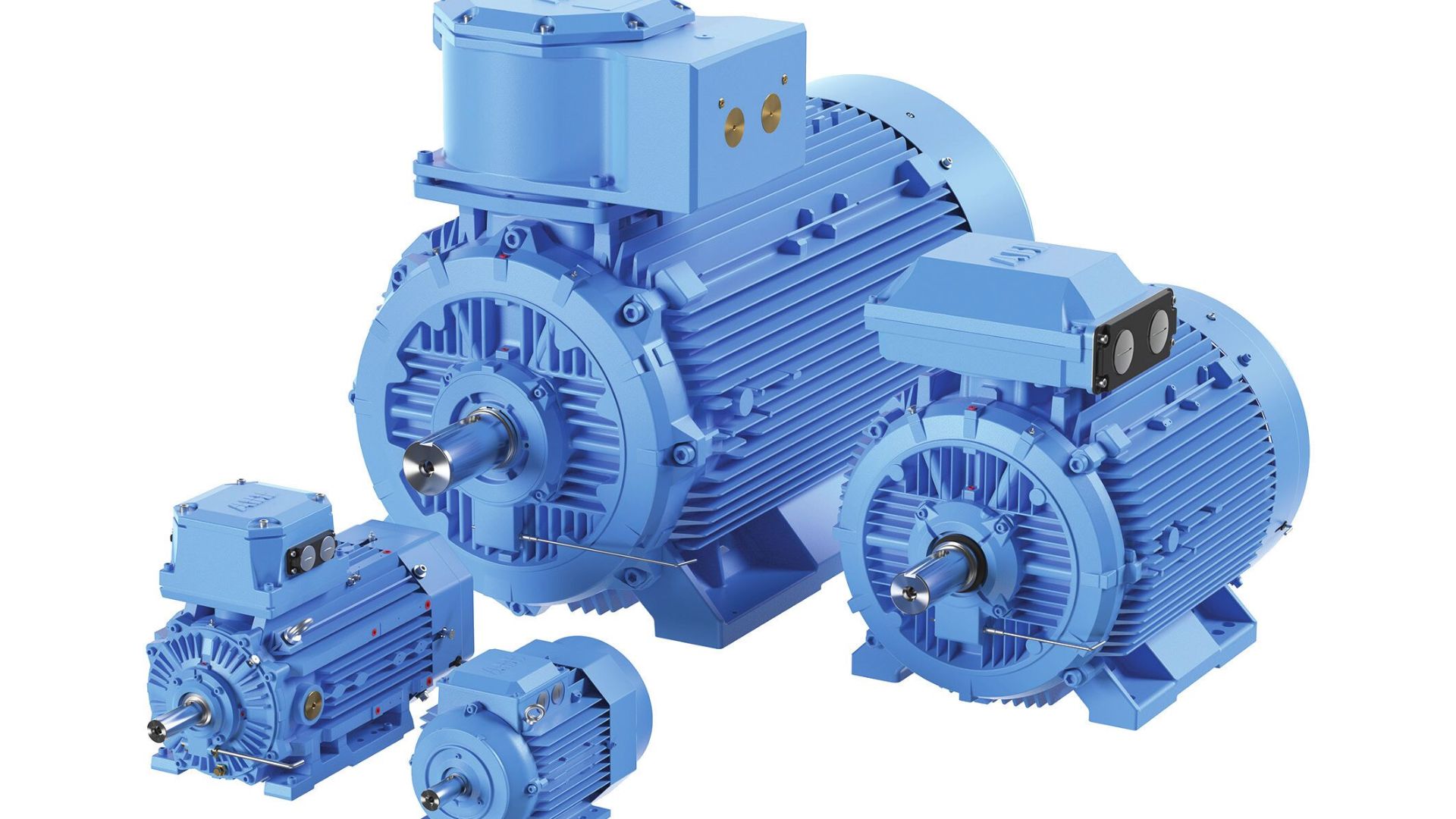

Explosion-proof motors are specially designed and constructed electrical motors that are engineered to prevent the ignition of flammable gases, vapors, liquids, or dust in hazardous environments. These motors are commonly used in industries such as oil and gas, chemical processing, mining, pharmaceuticals, and other applications where potentially explosive atmospheres may be present.

Most of the explosion-proof motors services offer maintenance, repair, and support of explosion-proof motors. These services ensure that the motors continue to operate safely and efficiently within their designated hazardous environments. It’s important to note that explosion-proof motors and their associated services are crucial for maintaining a safe working environment in industries where the risk of explosion is significant. These services help prevent potential disasters and ensure the continued operation of essential equipment.

What are the key aspects of explosion-proof control panels services?

Some key aspects of Explosion Proof Control Panels services include:

- Design and Customization: Creating control panel designs that meet the specific requirements of the hazardous environment, taking into consideration factors such as the classification of the hazardous area, temperature ranges, and the types of substances present.

- Component Selection: Choosing appropriate explosion-proof components, switches, relays, circuit breakers, and other electrical elements that are certified for use in explosive atmospheres.

- Installation and Wiring: Properly installing control panels in accordance with safety regulations and standards, ensuring correct wiring, grounding, and bonding to prevent the risk of sparks or ignition sources.

- Testing and Quality Assurance: Conduct thorough testing of control panels to verify their functionality, safety features, and compliance with relevant standards. This may involve insulation resistance tests, continuity checks, and functional tests.

How Can Explosion-Proof Motors Prevent Catastrophic Accidents?

Explosion-proof motors are designed and constructed with specific features and safeguards to prevent catastrophic accidents in environments where flammable gases, vapors, liquids, or dust are present. These motors play a crucial role in maintaining safety and preventing explosions. Here’s how explosion-proof motors help prevent catastrophic accidents:

- Enclosed Construction: Explosion-proof motors are enclosed in a robust and tightly sealed housing that prevents external explosive gases or dust from entering the motor’s internal components. This containment minimizes the likelihood of sparks or ignition sources inside the motor.

- Sealed Joints and Fittings: All joints, connections, and fittings on explosion-proof motors are tightly sealed to prevent the escape of hazardous gases or dust. This prevents potential ignition sources from interacting with the surrounding atmosphere.

- Pressure Release Mechanisms: Explosion-proof motors often include pressure relief mechanisms that allow built-up pressure within the motor to be safely released without causing an explosion. These mechanisms redirect pressure and heat away from sensitive components.

- Rugged Construction: Explosion-proof motors are built to withstand harsh conditions, shocks, and vibrations. This rugged construction helps prevent damage to internal components that could lead to sparks or other ignition sources.

While doing research surely you may come across varieties of services in terms of explosion-proof motors but choosing amongst them wisely is truly essential, so in that case you can reach out to us at Prolux International which offers you a reliable service.