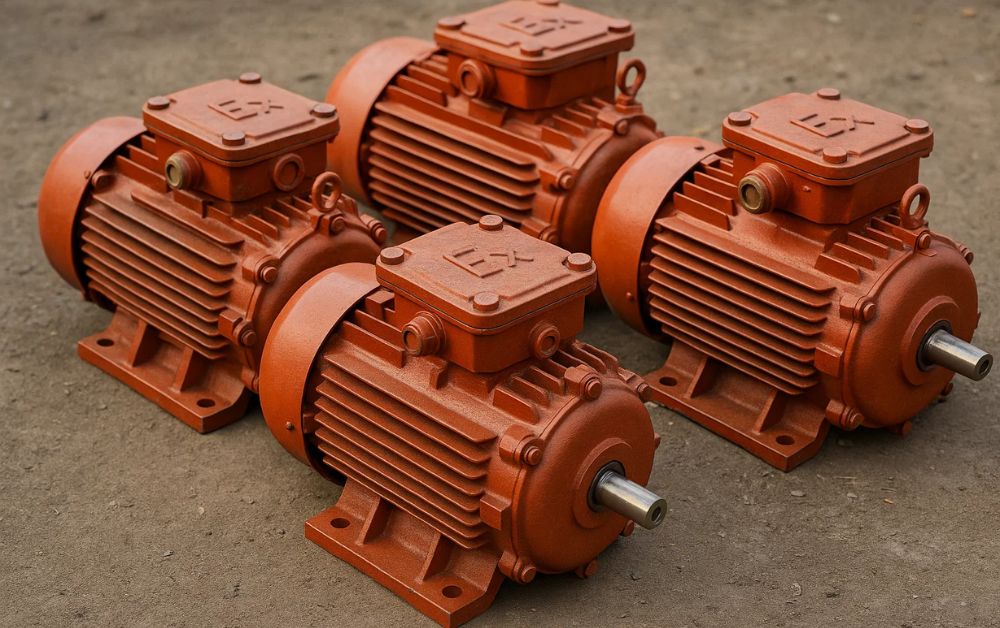

Industrial operations in hazardous environments need machinery that can operate safely under extreme conditions. One of the most critical pieces of equipment in such settings is the explosion-proof motor. These motors are planned to prevent ignition of surrounding gases, vapors, or dust, reducing the risk of catastrophic accidents. With rapid advancements in technology and growing safety standards, the design of explosion proof motors is evolving significantly. This article explores the emerging technologies & trends shaping modern motor design for hazardous environments.

Advanced Materials: Making Motors Safer

One of the most significant changes we’re seeing in explosion-proof motors is the shift toward better materials. In the past, these motors were built with heavy steel casings & basic insulation. But today, manufacturers are using stronger alloys, composite materials, & coatings that not only improve motor durability but also enhance heat dissipation.

What does this mean for safety? These advanced materials reduce the risk of ignition by effectively managing heat, a crucial factor in explosive environments. They also make motors more corrosion-resistant, enabling them to last longer & perform more reliably in harsh conditions.

Sealing Technology: Keeping Things Contained

Another area where we’re seeing significant improvements is in sealing technology. Traditional explosion-proof motors had enclosures & gaskets designed to prevent dangerous substances from entering the motor housing. Today, however, more precise, advanced sealing methods, such as labyrinth seals and epoxy encapsulation, give even better protection.

These improvements do not just make the motor safer; they also reduce maintenance. When dust and moisture can’t get into the motor, there’s less chance of performance issues down the line. This means fewer breakdowns and longer-lasting equipment.

Smart Sensors: A Step Towards Predictive Maintenance

Explosion-proof motors are becoming a lot smarter thanks to the integration of smart sensors. These sensors monitor temperature, vibration, & current levels in real-time. If something goes wrong—like a part overheating or a vibration getting out of control—the system can send an alert, giving operators a heads-up before things escalate into a bigger issue.

By connecting these sensors to a central monitoring system, operators can stay ahead of potential problems through predictive maintenance, reducing the risk of accidents and improving operational efficiency. This trend fits in perfectly with the rise of smart factories, where data-driven insights help improve both safety and productivity.

Energy Efficiency: Saving Money and Reducing Risk

As industries focus on sustainability, energy efficiency is now a key factor in motor design. New motors feature optimized windings, improved rotor designs, and low-friction bearings, all of which reduce energy consumption. This is great for the environment and your bottom line.

Why is this important for safety? More efficient motors generate less heat, which lowers the risk of ignition. Plus, using less energy aids you meet environmental regulations, which are becoming a higher priority for businesses worldwide.

Compact and Modular Designs: Flexibility and Ease of Maintenance

Explosion-proof motors of the past were often bulky and difficult to maintain, especially when you were working in tight spaces. But with the new trend toward compact and modular designs, these motors are more versatile than ever.

Now, motors are designed to be easily disassembled, with components that can be replaced or upgraded without replacing the whole motor. This approach means repairs are quicker and installations are easier, while maintaining high safety standards. It’s a win-win for industries that need flexibility and efficiency in their operations.

Advanced Cooling: Keeping It Cool Under Pressure

Heat management is always a concern in hazardous environments, & designers have tackled it head-on with advanced cooling techniques. Methods such as liquid cooling, forced air cooling, and even heat-pipe technology are now used to keep motors at optimal temperatures.

Why is this important? When motors generate too much heat, they become a safety hazard. These cooling technologies ensure motors run efficiently, reduce the risk of overheating, and ultimately last longer.

IoT and Remote Monitoring: The Future of Motor Management

The Industrial Internet of Things (IIoT) has been a game-changer for motor design, especially in hazardous environments. Remote monitoring is now possible, allowing operators to track motor performance from anywhere, whether they’re on-site or off.

The best part? If there’s an issue—whether it’s a vibration, temperature spike, or anything else—the system can alert you immediately, giving you the chance to take action before it turns into a bigger problem. This integration helps companies reduce maintenance costs, enhance safety, and extend the life of their motors.

Looking Ahead: What’s Next for Explosion-Proof Motors?

The future of explosion-proof motors is bright. We can expect even more innovations, like AI-powered predictive maintenance, lightweight composite materials, & eco-friendly manufacturing processes. As industries continue to face challenges, the demand for smarter, safer, and more adaptable motors will only increase.

Manufacturers that stay on top of emerging trends & technologies will be well-positioned to meet the increasing wants of industries worldwide.

In Conclusion

Explosion-proof motors are a cornerstone of safety in hazardous industrial environments. With advancements in materials, sealing technology, energy efficiency, & smart sensor integration, today’s motors are safer, more reliable, & more efficient than ever before. Suppose your business is seeking cutting-edge, explosion-proof motors that meet the highest safety standards. In that case, Prolux International LLC offers a range of products that deliver top performance in even the most demanding environments.