Industrial environments often expose electrical equipment to hazardous conditions where flammable gases, vapors, or dust are present. In such cases, standard motors may not provide sufficient protection, creating a risk of fires or explosions. This is where explosion proof motors play a vital role. These motors are specially engineered to withstand harsh conditions and ensure the safety of both people and property. But how exactly are they different from standard motors? Let’s break it down.

Difference Between Explosion Proof Motors & Standard Motors

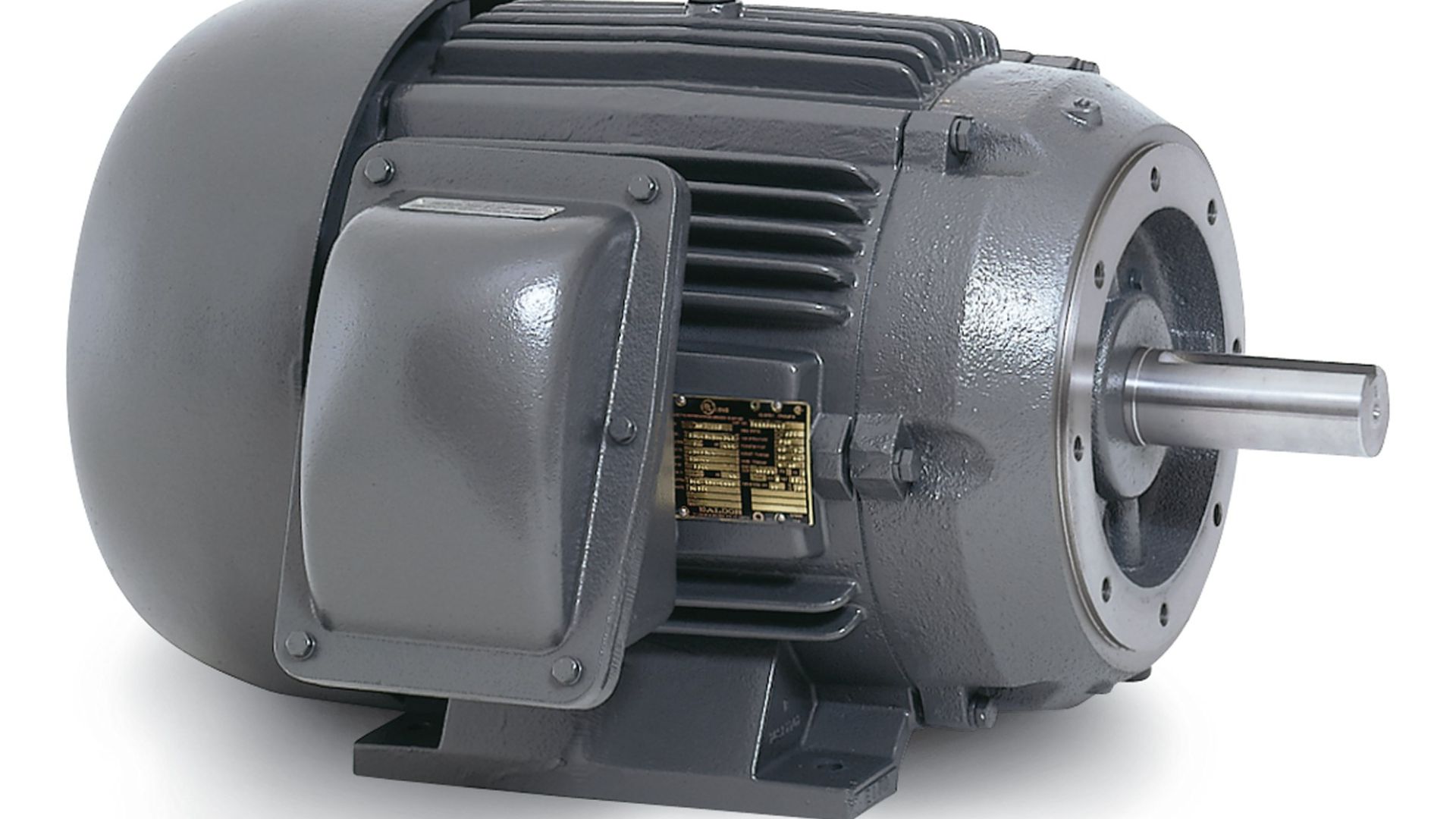

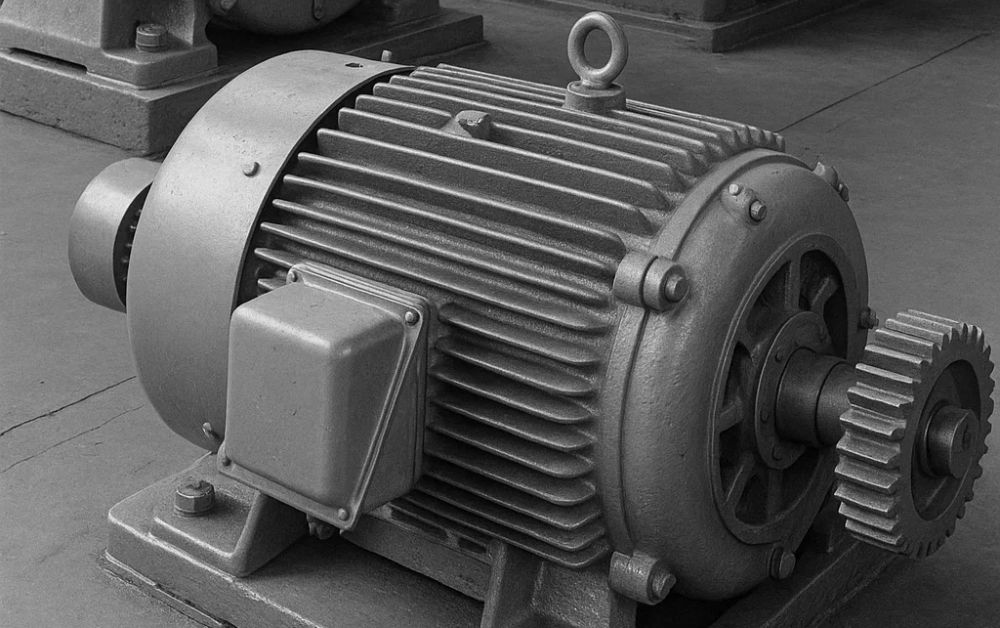

The primary difference lies in the motor’s design and its ability to contain any internal explosion without igniting the surrounding atmosphere. Standard motors are built for general applications where environmental hazards are minimal. On the other hand, explosion proof motors are constructed with reinforced enclosures and components that prevent sparks, flames, or hot surfaces from coming into contact with combustible materials in the external environment.

Key Design Features of Explosion Proof Motors

Motors have several unique design elements that set them apart from standard motors:

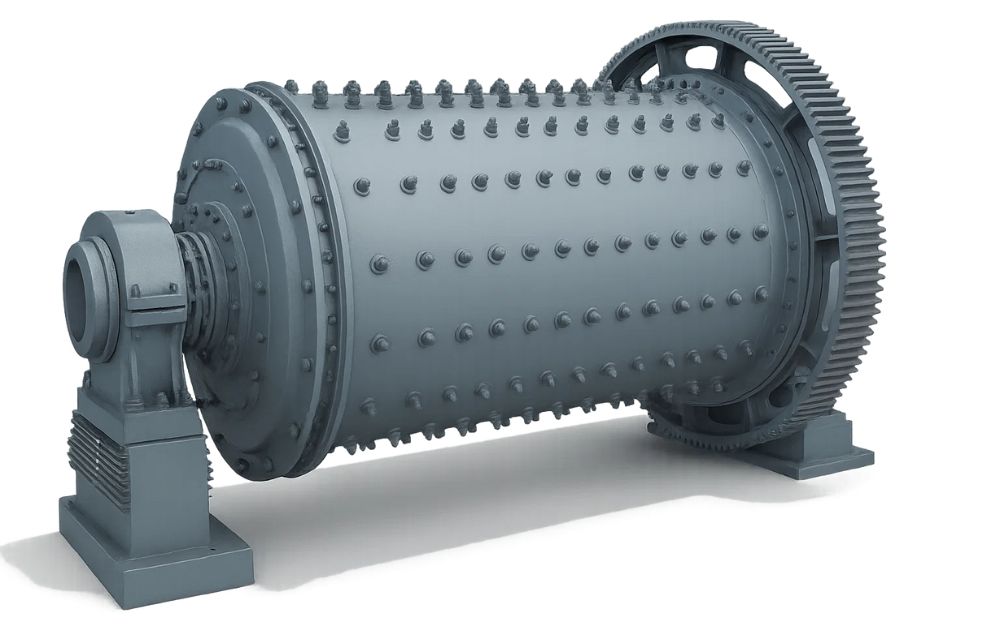

1. Heavy-Duty Enclosures

The enclosures are made of robust materials like cast iron, steel, or aluminum to contain any internal explosion. This prevents flames or hot gases from escaping the motor.

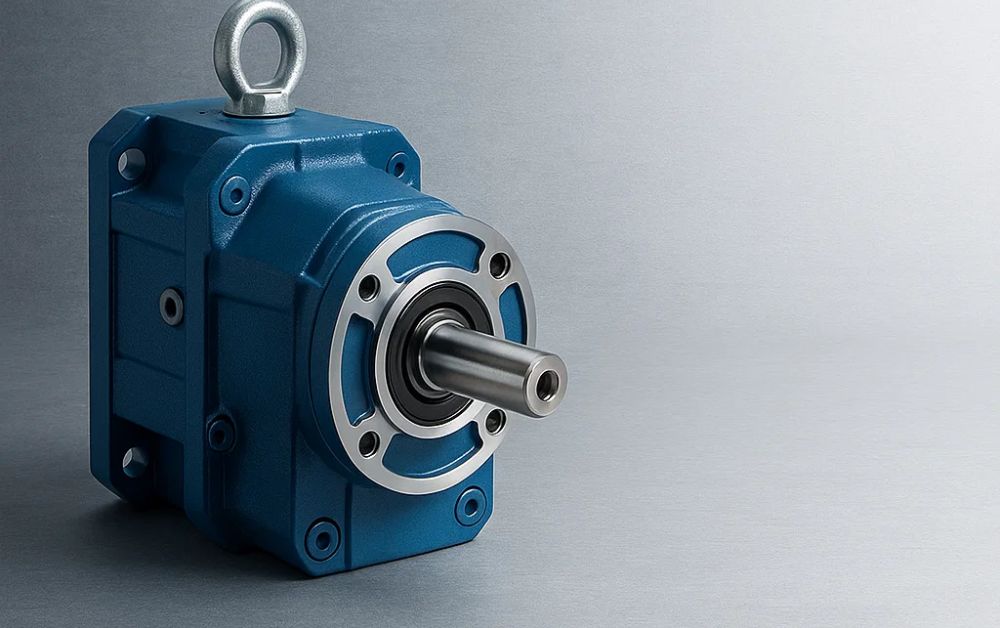

2. Flame Paths and Cooling

These motors have specially engineered flame paths that cool escaping gases to a safe temperature before they reach the outer environment.

3. Enhanced Sealing

Unlike standard motors, motors feature superior sealing mechanisms that prevent the entry of dust, vapors, or moisture into the internal components.

4. Stronger Bearings and Shafts

The internal components, including bearings and shafts, are designed to endure high levels of mechanical stress and vibration in hazardous conditions.

5. Temperature Control and Heat Dissipation

Explosion proof motors are designed to manage internal heat effectively. They use advanced cooling systems and high-temperature-resistant components to prevent the motor surface from becoming hot enough to ignite surrounding flammable materials.

Construction Standards and Certifications

Motors are built to comply with stringent safety standards, including ATEX, IECEx, or UL certifications. These certifications guarantee that the motor can operate safely in classified hazardous zones. Standard motors, while reliable for everyday use, do not undergo the same level of testing or certification required for hazardous environments.

Comparison Between Explosion Proof Motors & Standard Motors

| Feature | Explosion Proof Motors | Standard Motors |

| Enclosure Material | Cast iron, steel, aluminum alloy | Aluminum, steel, plastic |

| Enclosure Rating | NEMA 7, 9 / IP65-IP67 | NEMA 1-4 / IP44-IP55 |

| Flame Path Design | Precision-machined cooling paths | Not required |

| Internal Explosion Containment | Yes, tested to withstand internal pressure | No containment capability |

| Temperature Classification | T1-T6 classifications | Standard operating temperatures |

| Certification Requirements | ATEX, IECEx, UL, CSA mandatory | Optional efficiency certifications |

| Installation Cost | Higher due to specialized wiring | Standard installation practices |

| Operating Environments | Class I/II/III hazardous locations | Non-hazardous general purpose |

| Typical Lifespan | 15-20 years | 10-15 years |

| Maintenance Frequency | Scheduled inspections required | Standard preventive maintenance |

| Initial Investment | 200-300% of standard motor cost | Base cost reference |

| Insurance Benefits | Reduced premiums in hazardous facilities | Standard coverage |

Applications of Explosion Proof vs. Standard Motors

Standard motors are widely used in industries such as HVAC, agriculture, or manufacturing, where there is no threat of flammable substances. They are typically designed for efficiency, performance, and cost-effectiveness.

Motors, however, are used in:

- Oil and gas refineries.

- Chemical and petrochemical plants.

- Mining operations.

- Pharmaceutical and food processing industries.

- Grain storage facilities and distilleries.

These industries demand motors that can safely operate in the presence of explosive gases, fumes, or dust.

Benefits of Using Explosion Proof Motors

- Increased Safety: They prevent potential accidents in flammable atmospheres.

- Regulatory Compliance: They meet global safety standards required by specific industries.

- Longevity: Their heavy-duty construction ensures long-term reliability.

- Versatility: They can operate effectively in both indoor and outdoor hazardous zones.

When Should You Use Standard Motors?

Standard motors are ideal for non-hazardous applications where the operating environment does not pose risks of fire or explosion. For example, they work well in residential buildings, general manufacturing units, and commercial spaces where exposure to combustible materials is unlikely.

Selection Criteria for Explosion Proof Motors

Environmental Assessment Factors:

- Hazardous Material Classification (gas, vapor, dust type)

- Zone/Division Requirements (continuous, intermittent, abnormal presence)

- Temperature Class Determination (auto-ignition temperature of materials)

- Atmospheric Conditions (indoor/outdoor, corrosive elements)

- Installation Location (accessibility for maintenance)

Maintenance Best Practices

Inspection Schedule:

- Weekly: Visual inspection of enclosure integrity and label condition

- Monthly: Check mounting bolts and coupling alignment

- Quarterly: Measure insulation resistance and operating temperature

- Annually: Complete disassembly inspection by certified technicians

- As Needed: Flame path measurement and enclosure pressure testing

In Conclusion

The primary distinction between explosion proof motors and standard motors lies in their design, safety measures, and ability to handle hazardous environments. While standard motors are suitable for everyday applications, motors provide the critical protection needed in industries where safety is paramount.

For high-quality, certified motors designed to meet global safety standards, Prolux International LLC offers reliable solutions that ensure performance and safety in even the most challenging environments.

FAQ’s

1. How much do explosion proof motors cost compared to standard motors?

Explosion proof motors typically cost 2-3 times more than standard motors due to their specialized construction, heavy-duty enclosures, and certification requirements.

2. What certifications do explosion proof motors need?

Explosion proof motors must comply with various international standards including ATEX (European), IECEx (International), UL (North America), and CSA certifications.

3. How long do explosion proof motors last?

High-quality explosion proof motors typically last 15-20 years with proper maintenance, often outlasting standard motors due to their robust construction

4. Can explosion proof motors be used outdoors?

Yes, explosion proof motors are designed for both indoor and outdoor hazardous applications.

5. What maintenance do explosion proof motors require?

Explosion proof motors require regular inspection of enclosure integrity, flame path clearances, and sealing systems.