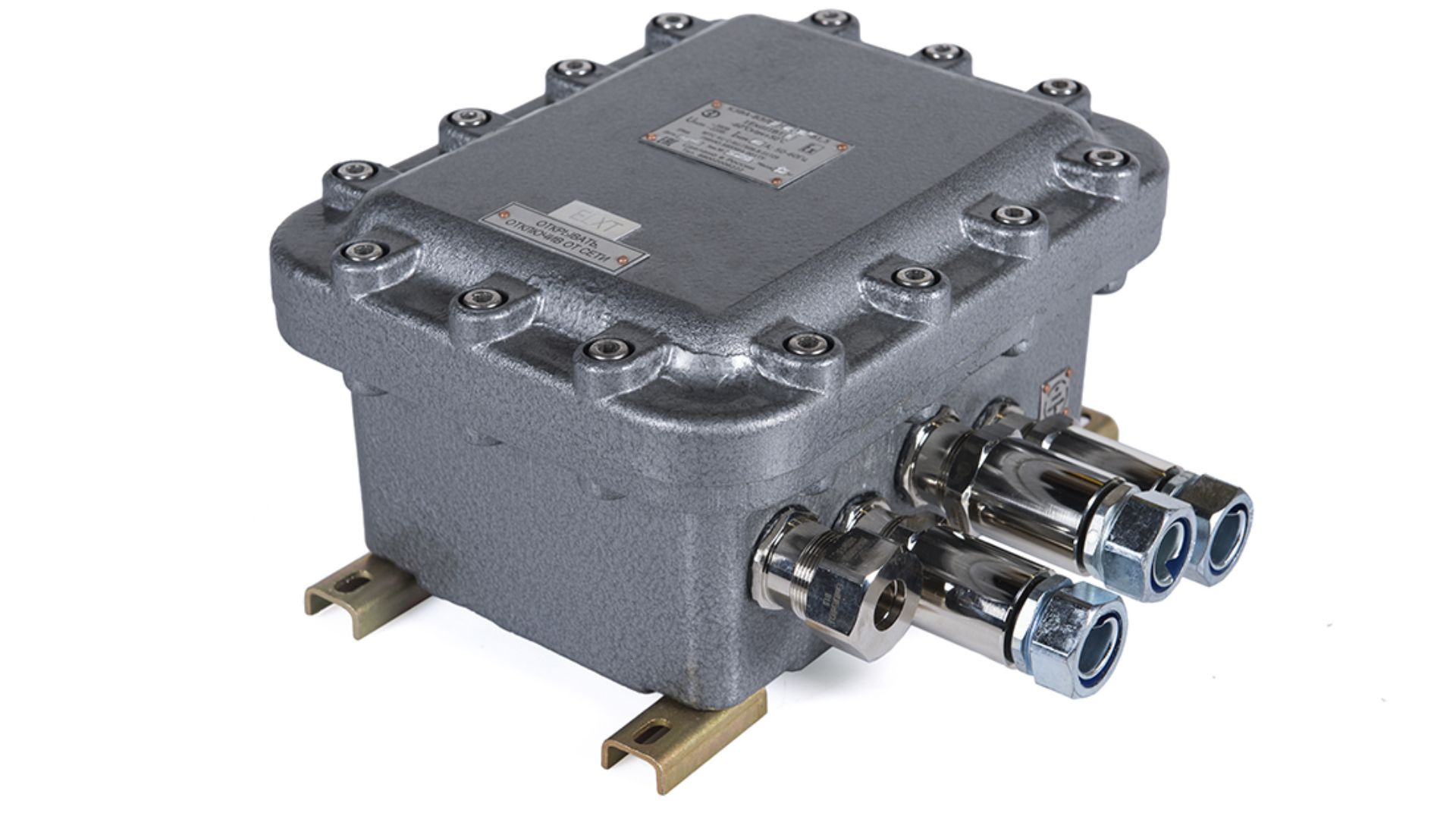

When it comes to guaranteeing electrical safety in hazardous environments, an explosion proof junction box plays a crucial role. These specialized electrical enclosures are designed to contain any sparks, heat, or explosions within the box itself, preventing them from igniting surrounding flammable gases, vapors, or dust. They are an essential safety solution for industries where volatile substances or hazardous conditions are present. But which industries rely on boxes the most? Let’s explore.

Why Use an Explosion Proof Junction Box?

Electrical systems in hazardous areas are prone to accidents if not adequately protected. A simple electrical spark can trigger catastrophic explosions in environments filled with flammable substances. A box ensures that:

- Sparks and heat from electrical components are contained.

- Flammable gases or vapors cannot enter the enclosure.

- Equipment complies with international safety standards like ATEX or IECEx.

- Downtime due to accidents is minimized, leading to uninterrupted operations.

For industries with high safety requirements, these boxes are not just an option—they are mandatory.

Industries That Rely on Boxes

Oil and Gas Industry

The oil and gas sector is one of the most hazardous industries in the world. Refineries, drilling rigs, and gas plants operate in environments with highly flammable gases and vapors. Even the smallest electrical fault can lead to devastating explosions.

Boxes are installed in:

- Offshore oil rigs.

- Onshore oil refineries.

- Gas processing plants.

- Storage and distribution terminals.

These boxes ensure that the electrical connections remain sealed and safe from the surrounding hazardous atmosphere.

Chemical and Petrochemical Plants

Chemical plants handle volatile substances like solvents, alcohols, and acids that can ignite easily. Electrical safety is a major concern in such environments, where a sole spark can lead to chain reactions.

Boxes provide the required safety by:

- Preventing internal sparks from escaping.

- Protecting electrical components from corrosive chemicals.

- Meeting the stringent safety codes applicable to chemical processing units.

Mining Industry

Mining operations, especially coal mining, deal with explosive gases like methane and coal dust, which can ignite easily under unsafe conditions. Miners operate heavy equipment and rely on electrical systems deep underground.

In such conditions, boxes:

- Prevent electrical sparks from triggering explosions.

- Protect wiring systems from dust, debris, and moisture.

- Ensure the safety of labors in confined spaces.

Pharmaceutical Manufacturing

The pharmaceutical industry uses various volatile chemicals during the production of drugs and other medical formulations. The mixing and packaging of chemicals can create hazardous atmospheres.

Using boxes in these facilities ensures that the electrical enclosures:

- Maintain a sealed and controlled environment.

- Reduce the risk of fire during production.

- Meet compliance standards for cleanroom safety.

Food and Beverage Industry

This industry might not seem hazardous at first glance, but certain processes—such as grain storage, sugar processing, and breweries—generate combustible dust. When mixed with air, this dust can become explosive.

Boxes are critical in:

- Grain silos and mills.

- Breweries and distilleries.

- Sugar refineries and packaging units.

Paint and Coating Factories

Paint, varnish, and coating materials contain flammable solvents. The process of mixing and spraying these substances creates an environment where explosions can occur easily.

Boxes in such facilities:

- Contain any electrical sparks from switches or connections.

- Prevent ignition of vapors and fumes.

- Provide a robust enclosure for electrical safety.

Waste Treatment Plants

Waste treatment plants often deal with gases like methane, hydrogen sulfide, and other hazardous compounds. The presence of these gases makes electrical safety a priority.

Installing boxes ensures that the electrical systems in waste treatment facilities are well-protected, minimizing risks of fire or explosion.

Key Features to Look for in a Box

When selecting a box for your facility, consider the following features:

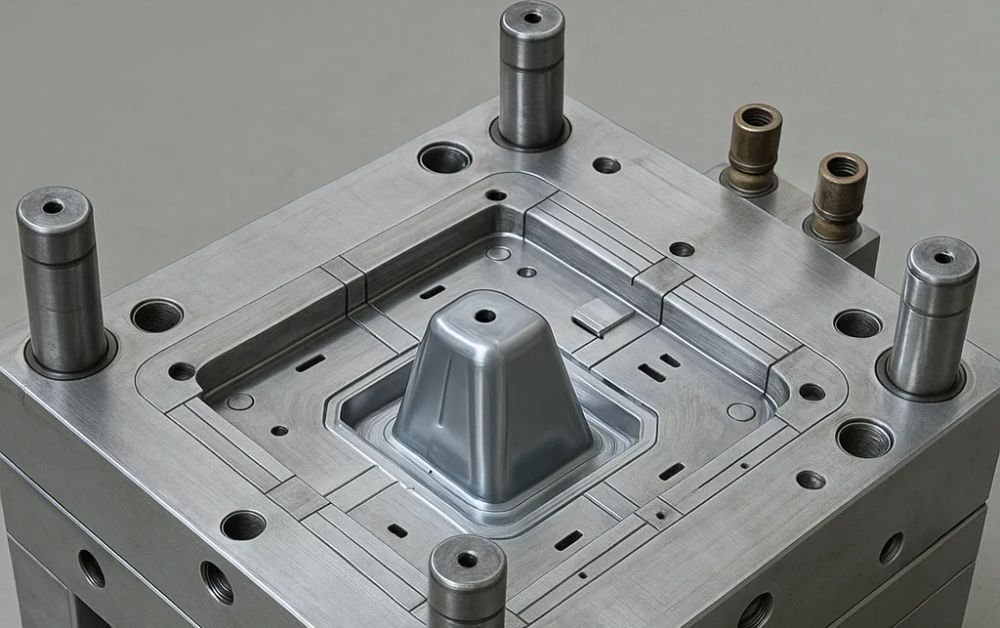

- Material Durability: Choose stainless steel, aluminum, or other corrosion-resistant materials.

- Ingress Protection (IP) Rating: Ensure the box is dustproof and waterproof.

- Temperature Rating: Check if it can withstand extreme heat or cold.

- Certification: Look for ATEX, UL, or IECEx certifications for compliance with global safety standards.

- Customizable Design: Opt for models that can be tailored to your specific industrial needs.

In Conclusion

A box is not just a safety device but a critical investment in preventing catastrophic accidents. Industries such as oil & gas, mining, chemical processing, and food manufacturing heavily rely on these boxes to maintain operational safety and compliance.

Looking for the best box for your industry? Prolux International LLC offers top-quality, certified solutions designed for maximum safety and durability.