In industries where flammable gases, vapors, or combustible dusts are prevalent, ensuring the highest level of safety is paramount. Explosion-proof enclosure play a crucial role in safeguarding electrical equipment from igniting potentially hazardous atmospheres. Let’s delve into the essential question: What are Explosion-Proof Enclosure Standards and how are they relevant, especially in regions like the UAE?

Defining Explosion-Proof Enclosures

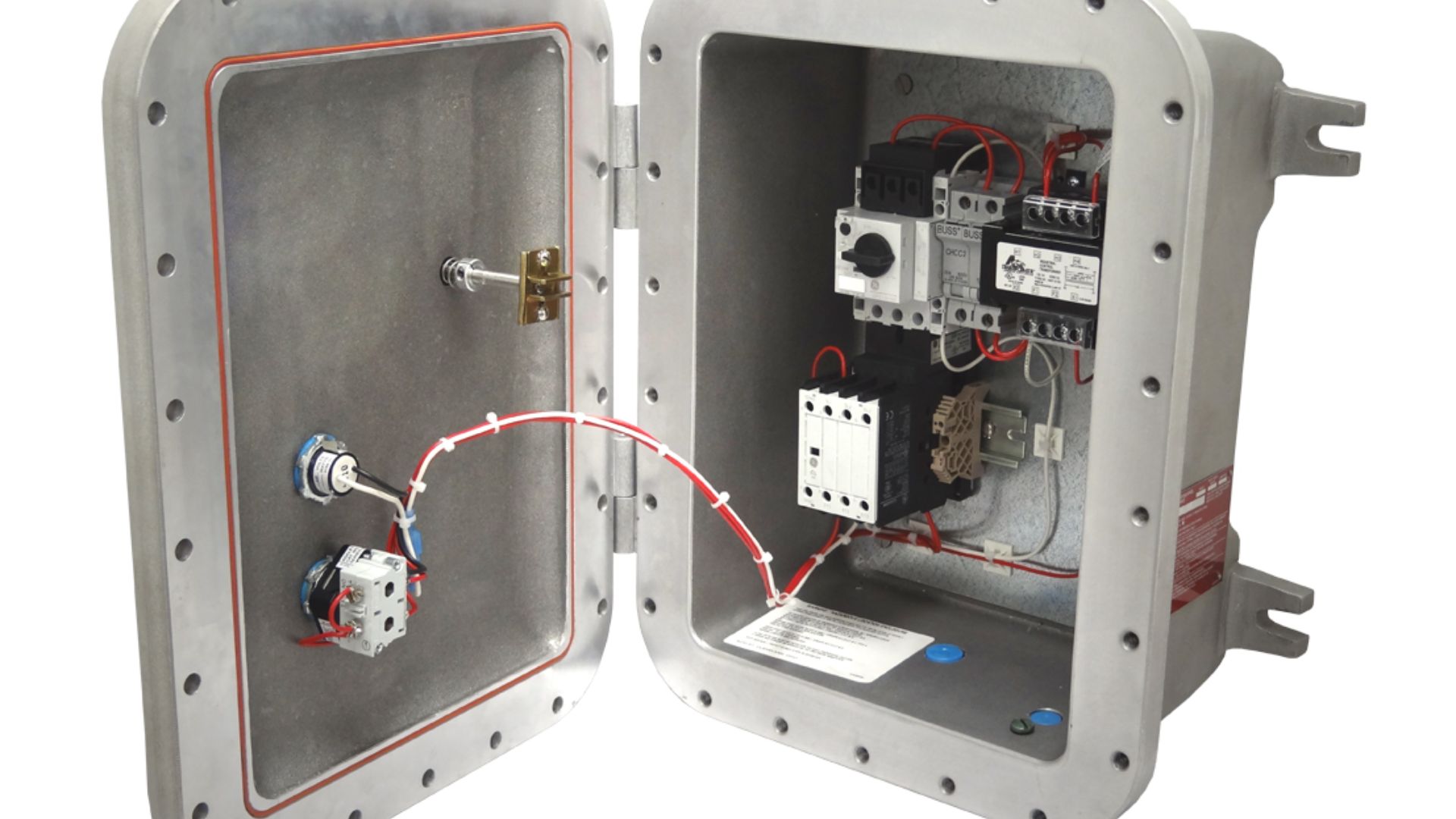

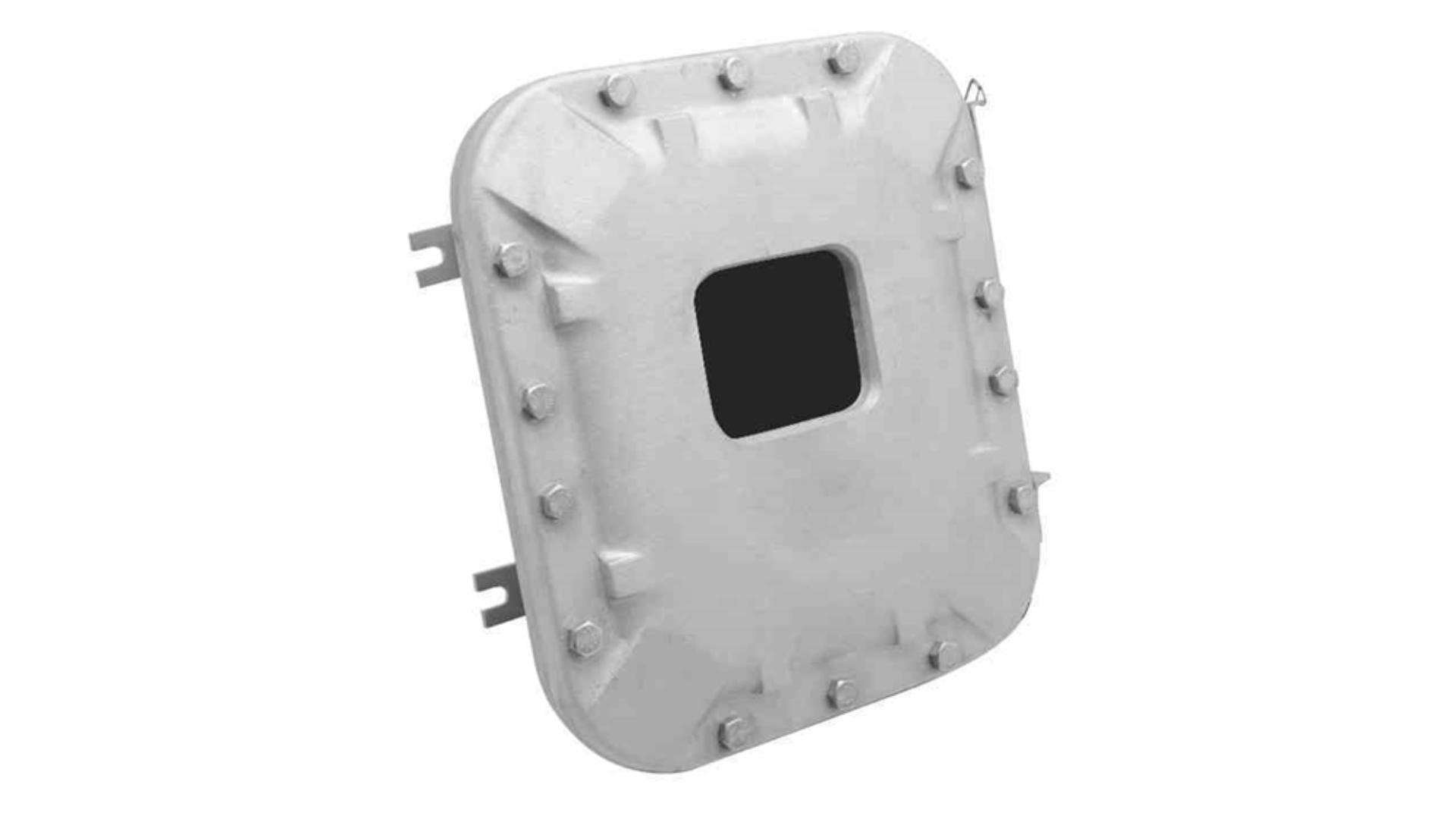

Explosion-proof enclosure in UAE are specially designed containers that house electrical components and prevent the ignition of flammable substances surrounding them. These enclosures are constructed to withstand and contain any internal explosion, thereby preventing the release of sparks or flames into the hazardous environment.

Explosion-Proof Enclosures in UAE

In the United Arab Emirates (UAE), a region with a significant presence of industries like oil and gas, petrochemicals, and manufacturing, adherence to rigorous safety standards is imperative. The UAE aligns with international norms and standards to ensure the reliability and effectiveness of explosion-proof enclosures used in its industrial landscape.

Companies operating in the UAE prioritize the implementation of explosion-proof enclosures to mitigate the risks associated with hazardous environments. These enclosures not only comply with global standards but also adhere to local regulations, emphasizing the commitment to safety and the well-being of personnel.

What Are Explosion Proof Enclosure Standards In UAE?

1.IEC Standards:

The IEC provides international standards for the design and testing of explosion-proof enclosures. IECEx, the IEC System for Certification to Standards Relating to Equipment for Use in Explosive Atmospheres, is a widely recognized certification system for equipment used in hazardous areas.

2.Local Authorities and Regulations:

Local authorities and regulatory bodies in the UAE, such as the Emirates Authority for Standardization and Metrology (ESMA), may establish specific requirements for explosion-proof enclosures. These regulations could be based on international standards or adapted to local conditions.

3.ATEX Directive:

While the ATEX Directive is specific to the European Union, some countries and industries worldwide use it as a reference. It provides standards for equipment intended for use in potentially explosive atmospheres.

4.NFPA Codes:

The National Fire Protection Association (NFPA) codes and standards, such as NFPA 70 (National Electrical Code) and NFPA 496 (Standard for Purged and Pressurized Enclosures for Electrical Equipment), are recognized internationally and might be considered or referenced in safety regulations.

Benefits of Explosion-Proof Enclosures

1.Risk Mitigation: Explosion-proof enclosures significantly reduce the risk of ignition in environments with flammable substances, contributing to overall safety.

2.Compliance: Adhering to international and regional standards ensures compliance with regulatory requirements, minimizing legal and operational risks.

3.Equipment Protection: By housing electrical components within explosion-proof enclosures, the lifespan and reliability of critical equipment are extended, reducing the likelihood of failures.

Conclusion

In conclusion, understanding and implementing explosion-proof enclosure standards is fundamental to creating a safe working environment, particularly in regions like the UAE with stringent safety protocols. These standards provide a framework for designing, testing, and certifying enclosures, ensuring that industries operate with the highest level of safety and compliance.